Outcomes

Operations That Get Better Over Time

Productiv owns execution and continuous improvement—so performance compounds instead of plateauing.

Delivering Outcomes For:

Operational disruptions reduced

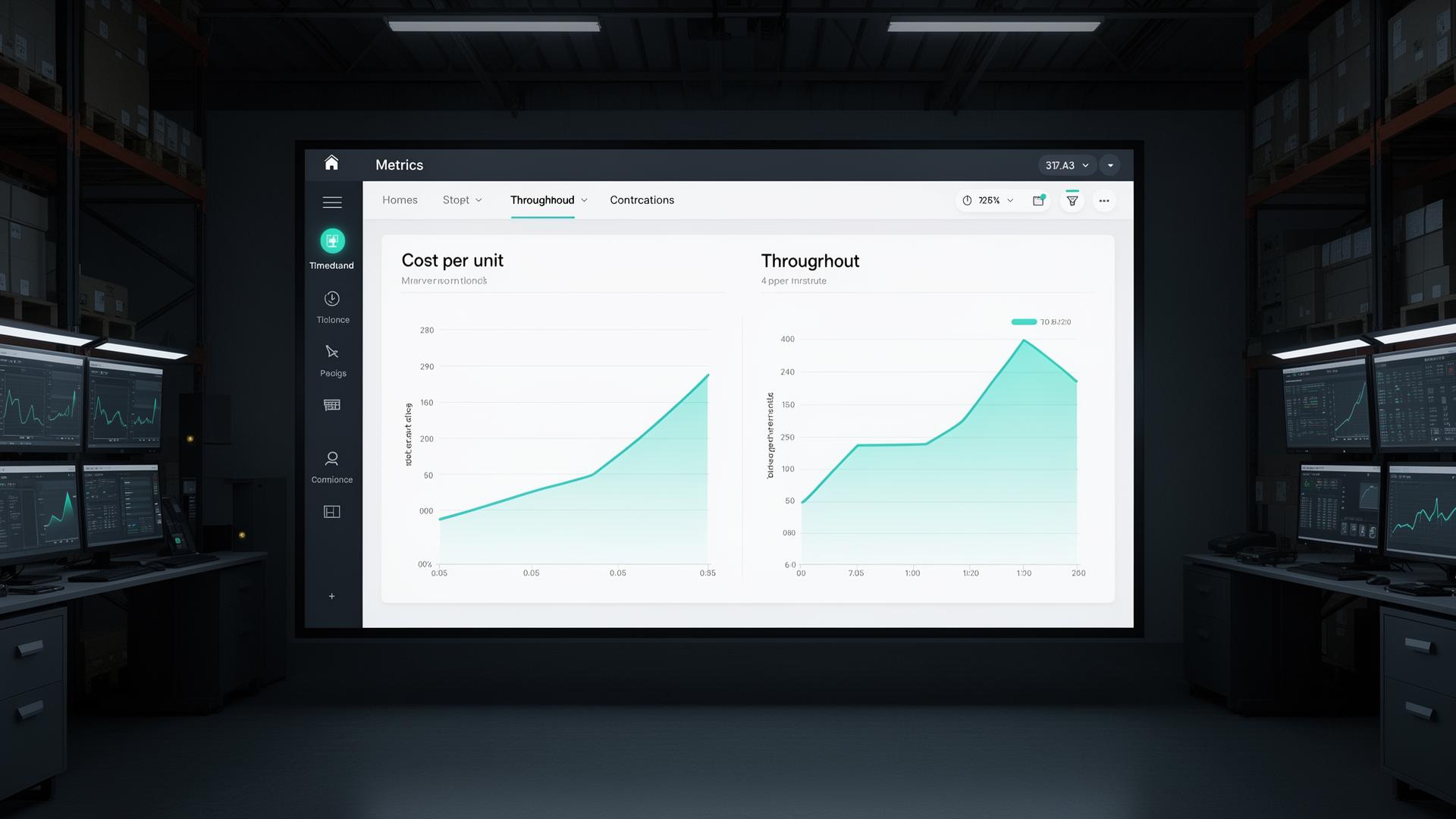

Units per hour — continuous growth

Typical improvement trajectory over 6 months

Most Providers Measure Activity. We Measure Progress.

If results don't improve, the model isn't working.

- Activity

- Hours

- Space

Orders shipped, hours worked, space used—activity metrics that don't require improvement.

We track the compound performance of the entire operation.

Outcomes that must improve as volume and complexity increase.

Cost per Unit

Declines or stabilizes as volume grows

Throughput & Capacity

More output without linear increases in labor or space

Reliability & Quality

Fewer errors, fewer escalations, more predictable performance

Labor Dependence

Reduced reliance on entry-level labor over time

[ SCOPE_NOTE ] These outcomes apply whether the operation is embedded in your facility or run inside Productiv's warehouses.

What This Looks Like in the Real World

Examples of how Productiv delivers outcomes across embedded operations and Productiv Network environments.

Poo-Pourri

High-growth omnichannel brand with complex fulfillment and peak season volatility

What Was Breaking

- Kitting behind creating OTIF issues for fulfillment

- SLA inconsistency during growth periods

- Operational issues requiring constant leadership attention

What Changed

- Execution ownership transferred to Productiv

- Continuous improvement cadence established

- Operations moved from reactive to proactive

Consistent SLA performance with operations in 'fine-tuning' mode after two years

"We are hitting all the SLAs over and over again. Productiv has led the charge and brought so many improvements to the table over the last two years. There's nothing glaring that stands out anymore and now we are just fine tuning."

Safeguard Medical

Medical device manufacturer requiring precision assembly and compliance

What Was Breaking

- Heavy management burden on internal engineering team

- Process handoffs requiring constant oversight

- Production planning bottlenecked by coordination

What Changed

- Process ownership transferred to Productiv

- Minimal interaction required from customer team

- Reliable turnaround without escalation

Reduced management burden—operations run with minimal customer intervention

"When we set the process, it just works. We send in the material. It gets packed out and turned around to us. So there's minimal interaction that we have to do. That's something that I like about them."

Buzzy Seeds

Seasonal product with variable demand and multi-channel distribution

What Was Breaking

- End-to-end execution inconsistency

- Planning complexity absorbing internal resources

- Coordination gaps across production and transportation

What Changed

- Smooth end-to-end execution established

- Account team providing consistent performance

- Planning burden reduced for internal team

Flawless execution enabling internal team to focus on planning, not firefighting

"Productiv has a very good team on our account, they've made it run very smooth, and they've done it pretty flawlessly. I do production planning and transportation so for it to go smooth from beginning to end is really important for my job."

Orora Landsberg

Enterprise packaging company with diverse project requirements

What Was Breaking

- Vendor fatigue after initial project honeymoon

- Declining attention and flexibility over time

- Projects treated as transactions, not partnerships

What Changed

- Consistent engagement quality across projects

- Flexibility maintained as relationship scaled

- Ownership mentality regardless of project number

Sustained partnership quality through 8+ projects with no degradation in attention

"They're always treating us like a new customer whether its the first project or the 8th project. They come to the table with an open concept of 'we're going to make it work', whatever you need."

Proven Results Across Industries

From disaster relief to manufacturing optimization—here are real examples of how Productiv delivers measurable outcomes.

Hurricane Relief Meals

Challenge

Mobilize partners and teams quickly to assemble 150,000 grocery boxes for Hurricane Maria disaster relief.

Solution

Immediately stand up a 100+ person operation with leased space, equipment, conveyors and goods.

Packaged and delivered 2.7 million meals in just 33 days to citizens in Puerto Rico.

Repackaging Paper Goods For Retail

Challenge

Operational inefficiencies and an over-reliance on temp workers were driving up labor costs with no output gain.

Solution

Using fixed unit pricing and lean-engineered workflows, implemented an on-site program to create efficiencies and reduce costs.

Over 3 million cases of product with 300 unique SKUs processed annually for 35% annual labor savings.

Building Stand-up Displays

Challenge

Client was losing track of perishable inventory and had excess corrugated displays for fast-growing product line.

Solution

Implemented WMS within 2 weeks. Combined WMS data with full inventory count to sort by batch/lot and quickly build displays.

Reduced total materials by 25% and excess materials by 90%.

Health & Beauty DTC Ecommerce

Challenge

New ecommerce site growing rapidly from startup to 5,000 orders/day with substantial order fulfillment backlog.

Solution

Built end-to-end fulfillment operation with OMS and WMS: inventory system, integrated EDI, shipping, and efficient pick pack line.

Shipped 450K+ orders in first 4 months. Achieved platinum 99.999% accuracy rating.

FBA, Ecomm & EDI Integration

Challenge

Needed turnkey fulfillment for Amazon FBA, B2C and EDI into retail on short timeline to meet global retailer demand.

Solution

Quickly integrated WMS with ERP, set up EDI portals with major retailers, domestic and international shipping for B2C, and Amazon FBA program.

Achieved on-time and accuracy SLAs while distributing products globally within 2 months.

Health & Beauty Throughput

Challenge

Manufacturer of health and beauty products was growing and demand for output was exceeding current capacity.

Solution

After trial with Productiv teams, on-site workforce grew to manage over 70% of client's labor-intensive lines and processes.

7-year partnership with 100% increase in output and 20% decrease in costs.

Revenue Increase With Printing Company

Challenge

Printing company wanted to offer clients hand work as part of their solution but lacked in-house expertise in pricing and executing handwork.

Solution

Placed a Supervisor on site, hired existing handwork department. Provides real time pricing to print estimators and manages all hand packaging projects.

Additional services offered for incremental revenue stream with locked-in pricing for accurate estimates.

Medical Device Throughput & Quality

Challenge

Internal teams were not keeping up with hospital demand for multiple versions of medical kits.

Solution

On-site program implemented to improve throughput and quality. Restored warehouse inventory to optimal levels.

Using 'The Productiv Way', teams increased throughput 20%-50%, even for complex 65-item kits.

Sprint Capacity For Mislabeled Product

Challenge

1.5 million lip balms from a global brand arrived from Asia mislabeled.

Solution

Productiv teams inspected and repacked every beauty kit to be store-ready for the holiday season.

500 pallets arrived in one day and were inspected, reworked and salvaged for retail in just 22 days.

Sorting & Tagging Apparel for Resale

Challenge

175,000 pieces of apparel across 50 SKUs needed to be sorted, tagged, and repackaged into strict carton configurations for resale through a new channel.

Solution

Built a custom sorting algorithm that generated carton-specific pick lists, then executed assembly-line style pick and pack with zero inventory waste.

7,000+ retail-ready cartons with 24 units each—delivered in just 14 days.

Learn more about this serviceWhat's Consistent Across Every Engagement

Across customers, industries, and deployment models, the same patterns emerge:

- Improvement does not depend on customer heroics

- Automation happens because the model requires it

- Labor stops being the default answer

- Operations become calmer as they scale

- Leadership gets time back

These are not one-off wins. They are the result of how Productiv is structured.

Who These Outcomes Are For

Productiv outcomes are strongest for organizations that:

- COMPATIBLEAre operating at scale or growing fast

- COMPATIBLEWant fewer operational escalations, not more dashboards

- COMPATIBLEExpect partners to own results—not just tasks

- COMPATIBLEBelieve operations should improve over time

If success is defined as "keeping up," Productiv is not the right model.

Outcomes Aren't a Promise. They're the Design.

Productiv doesn't optimize activity—we redesign operations so performance improves as volume grows. Whether embedded in your facility or operated in ours, outcomes are owned, measured, and expected to compound over time.

Talk to Productiv